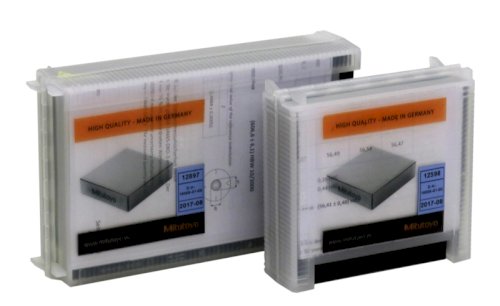

Skúšobná doštička tvrdosti 72 HRBW Rockwell ISO 6508-3 s certifikátom DAkkS 60x60x16mm hliník MITUTOYO (63ETB023)

| Pôvodná cena | 416 EUR |

| Vaša cena bez DPH | 416 EUR |

| DPH: | 23% |

| Jednotka: | ks |

| Kód 1: | 63ETB023 |

| Značka: | Mitutoyo |

Popis

Hardness reference materials in quality control:

The boost for your process safety! The daily verification, performed by the user, is described in the according hardness testing standards and significantly contributes to quality management processes.

In the daily verification process, all parameters of the hardness test system that build up to the hardness value, are examined by indentations on the hardness reference material.

This periodical inspection of the machine by means of hardness reference materials should be carried out immediately before the daily start of the test schedule.

An according documentation enhances the process safety, as value shifts due to damage or malfunction can be detected easily.

In addition, the repeatability of results of the hardness testing machine can also be checked with the hardness reference materials.

Mitutoyo offers a comprehensive range of hardness reference materials (hardness test blocks) in different materials with hardness levels to suit your quality management procedure perfectly.

Mitutoyo reference materials:

High-end quality Made in Germany - Independent DAkkS calibration according to DIN EN ISO 6508 and/or ASTM E18 in an accredited laboratory Large square or rectangular surface with large space advantage over triangular or round test blocks Short delivery time MPE "Maximum Permissible Error" of the hardness testing system engraved (does apply for carbide materials) – all relevant information at a glance.

A range of additional services can be ordered:

- Up to three different scales on one reference material (Does not apply for Brinell materials)

- A lasered grid on the surface for accurate indentation spacing

- Alternative ASTM accredited calibration.

- Double calibration according to ISO and ASTM standards

- Compare the surface sizes for the evaluation of the price - performance ratio.

| Popis: | Volitelná dostupnost: |

| kalibrace až 3 zkušebních vah na jednom zkušebním bloku | |

| kalibrace podle ASTM E18 | |

| laserovaná mřížka pro přesné rozestupy vtisků | |

| Funkce: | 1. Rockwell zkušební destička s DAkkS / ISO certifikátem |

| Metoda: | Rockwell |

| Materiál: | hliník |

| Hodnota tvrdosti: | 72 |

| Scale 1: | HRBW |

| Vnikové tělísko: | Kuličkové vnikové tělísko |

| Průměr kuličky [mm]: | 1,5875 |

| Preliminary Test Force N: | 98.07 |

| Standardní: | ISO 6508-3 |

| Preliminary Test Force kgf: | 10 |

| Test Force N: | 980,7 |

| Test Force kgf: | 100 |

| Accreditation body: | DAkkS |

| Accreditation standard: | ISO 17025 |

| Rozměr: | 60x60x16mm |

| Surface: | 3.600 mm2 |

| Čistá váha: | 160 g |

| Gross weight: | 270 g |

| Produktová řada: | HR-110MR |

| HR-210MR | |

| HR-320MS | |

| HR-430MR | |

| HR-430MS | |

| HR-530 | |

| HR-610 | |

| HR-620 |

Médiá

Technická špecifikácia

Parametry produktu

| Rozměr |

Rozměr

60x60x16 |

| Jednotka |

Jednotka

mm |

| Provedení |

Provedení

zkušební destička tvrdosti |